IT & OT systems enhancement

Plexus helps integrate disparate OT Systems through AR/VR/IoT combined solution provided by multiple OEMs through APIs and helps visualize remotely the current state of assets, consumable and service delays. It can track the release process, through image & video analytics coupled with VR solutions to develop Real-time and predictive insights on the operation of critical equipment.

Key Features:

Augmented Reality Combined with DL

Augmented Reality Combined with DL

Virtual Reality:

Mixed Reality:

Track & Trace Solutions

Contemporary logistics systems are complicated and extremely hardware intensive, making them unfeasible at large. This needs a paradigm shift in logistic business with a technology adaptive solution. Plexus “Track-and –Trace is" – AR/VR App based solution, provides an end-to-end solution that fuses innovation with agility and precision as required by logistic operations and enables organisations to achieve high performance.

Virtual Training & Learning:

Digital work instructions are very important in a shop-floor & always has quality & compliance issues. Besides workers need job aid that help them at every step. This issue get enhanced further if the worker is new and doesn’t have much experience with processes, machines and tools. Plexus Virtual reality solutions coupled with DWI (Digital Work Instructions) help an operator practice in a virtual environment by interacting with its nearby tools and machines. The operator can also use it live in all the operations of the plant get the guidance using VR solutions plugged to his gadget (helmet) displaying the proper way of performing a task right in front of him. This reduces the cost associated with real-life training and eliminates the risk of machine & process failures.

Designing in a virtual environment:

Virtual Reality also encourages designing in a simulated environment. By wearing a head-mounted display a user can recreate a manufacturing line in the virtual world, and locate potential hazard points even before the component is developed in real life. Designing parts in a virtual environment will also reduce the cost associated with building a prototype or model of the component, and allow the user to eliminate errors in the design itself.

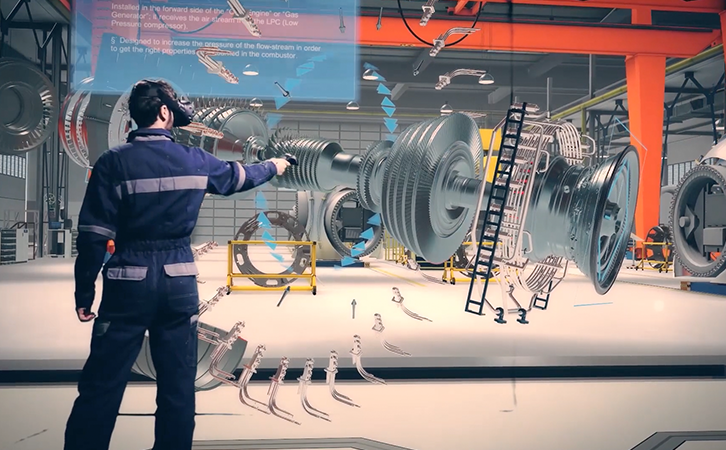

Maintenance and Inspection through AR:

Inspecting and maintaining the quality of an assembly/manufacturing has become quite easier through augmented and virtual reality solutions. An inspection specialist with a mixed reality headset like HoloLens can visit its facility and safely inspect and conduct routine maintenance of equipment by following the instructions visible on the screen. This will also allow the quality inspector to conduct frequent inspections easily, at a low cost. A virtual walk-through of the workshop can be performed more frequently by an expert.

Artificial Intelligence:

Plexus Explainable AI models are built with ML & DL models & can be integrated with all our AR VR solutions that can be deployed to augment and replace human decision making. The advanced AI models are complex black boxes are not able to explain why they reached a specific recommendation or a decision. Explainable AI in data science and ML platforms, for example, auto-generates an explanation of models in terms of accuracy, attributes, model statistics and features in natural language. This helps deliver seamless experiences to customers and achieve enhance operational efficiency.

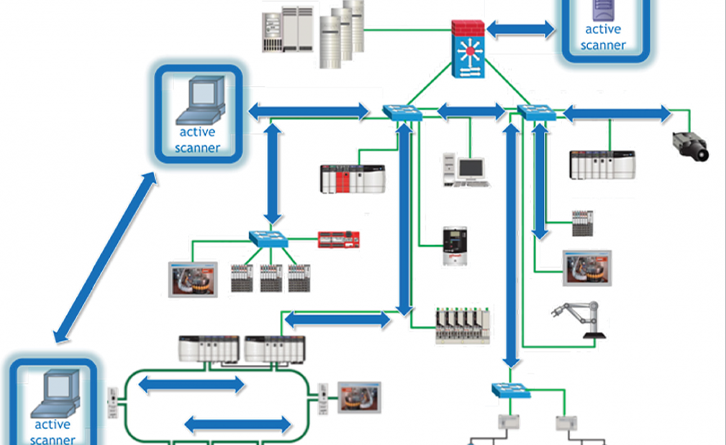

IoT in Healthcare, Pharma & Medical Devices

IoT requires a comprehensive ecosystem to leverage the best-of-breed and industry graded disparate solutions, using disruptive technologies and platform to meet customer expectation and industry 4.0 needs. Plexus solutions work with Google, Microsoft & AWS Platforms that enables a comprehensive ecosystem of customers, partners, start-ups and developer communities to quickly establish, demonstrate and monazite enterprise grade IoT-backed AR/VR applications in a secure, configurable and scalable manner. IoT allows the machines and hardware equipment of the industry to interact with each other on a shared network. These connected machines can be operated from a remote distance and monitored using VR solutions to improve the productivity and efficiency of the company.